Electrical panel labels are an after thought because they’re applied after installation. These generally include breaker box labels and circuit breaker labels. Find these here Shop Google for Breaker Box Labels

Control panel labels require forethought because they’re an integral part of control panel design and production. Control panel builders produce control panel labels tags and nameplates using in-house equipment.

- Door labels for panel and manufacturer identification.

- Door nameplates for operator device identification.

- Interior device tags for component and terminal identification.

The best control panel labels, tags and nameplates are multi-color graphic laminates. Sign companies use them everywhere because they’re so flexible and durable. Most control panel builders produce engraved plastic tags or engraved metal name plates because they have the equipment.

1 • Multi-Color Graphic Laminates

Most panel builders don’t produce multi-color graphic laminates because of the high equipment cost. We made the investment so we could produce them in-house instead of having to purchase them.

Most panel builders don’t produce multi-color graphic laminates because of the high equipment cost. We made the investment so we could produce them in-house instead of having to purchase them.

Our panel labels tags and nameplates are produced as multi-color graphic laminates so they all look sharp and consistent.

- Door labels to identify the panel and manufacturer.

- Door nameplates to identify door devices.

- Interior device tags to identify components and terminals.

The label to the right shows the benefits of using a Multi-Color Graphic Door Laminate. One label includes the customer’s corporate identity, operator device functionality, safety labels, and a Made in America label.

2 • Engraved Plastic Tags

Most panel builders make engraved plastic tags because they were the standard for twenty years. Engraved plastic tags work fine and are durable, but they are not as flexible as multi-color graphic laminates.

Most panel builders make engraved plastic tags because they were the standard for twenty years. Engraved plastic tags work fine and are durable, but they are not as flexible as multi-color graphic laminates.

Engraving sheet plastic has two color layers. The engraver cuts away the top layer to expose the bottom layer. You can only produce simple shapes and their minimum size makes them impractical for interior device tags.

- Door labels to identify the panel and manufacturer.

- Door nameplates to identify operator devices.

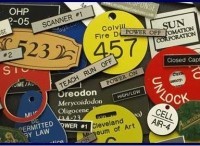

The labels to the right show the limitations of using engraved plastic tags on the control panel door. Compared to a multi-color graphic laminate they look old and many engraved plastic tags are needed in place of one Multi-Color Graphic Door Laminate.

3 • Engraved Metal Nameplates

Many panel builders produce engraved metal nameplates because they were the standard before plastic engraved tags. Engraved metal nameplates work fine, but are not as flexible as engraved plastic tags.

Many panel builders produce engraved metal nameplates because they were the standard before plastic engraved tags. Engraved metal nameplates work fine, but are not as flexible as engraved plastic tags.

Engraved metal nameplates are two color. Gray metal tag with a protective top coat. The engraver cuts away the protective coating to expose the bare metal, which turns black when exposed to an acid wash.

- Door labels to identify the panel and manufacturer.

- Door nameplates to identify operator devices.

The labels to the right show the limitations of using engraved metal tags on the control panel door. Compared to a multi-color graphic laminate they look old and many engraved metal nameplates are needed in place of one Multi-Color Graphic Door Laminate.