Control panel design basics are simple. Cost is always important, but so is an attractive appearance, simple operator controls and reliable operation. Simple panel designs are less expensive to produce and easier to operate and maintain.

It helps when you understand design is a process. Often you think you know exactly what you want when you get started and find you want something different when you’re done.

When you first put your design requirements on paper they seem unorganized. That’s normal. No one gets everything right in one pass. Design is a process and it takes time to get it right.

Rewrite your requirements until they’re properly organized and clear. Understand what you want, write it down using clear language, then proceed with the actual hardware design.

1 • start physical

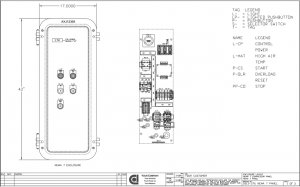

Good control panel design includes physical and electrical requirements. Don’t shortcut the design process and produce schematic drawings without producing physical layout drawings. Alternate between the physical and electrical until all potential problems have been solved.

Good control panel design includes accurate physical layout drawings and schematic drawings. This minimizes problems and delivery delays due to unresolved physical layout problems discovered during production or testing.

Good control panel design includes accurate physical layout drawings and schematic drawings. This minimizes problems and delivery delays due to unresolved physical layout problems discovered during production or testing.

Include National Electric Code (NEC) required clearance for power wiring and Underwriters Laboratories (UL) required clearance around heat producing devices.

- NEC requires bending radius clearance for incoming and outgoing power connections to insure the installing electrician has adequate room to make their power connections,

- UL requires manufacturer recommended clearance for heat producing devices (Programmable Logic Controllers, Variable Frequency Drives, etc.) to insure for adequate room for ventilation.

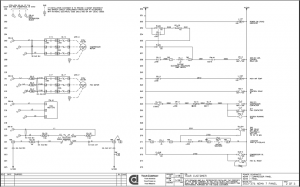

2 • analyze the power circuits

Identify each power circuit and determine the required wire size and circuit protection. The right wire size insures the circuit can deliver the required load current. The right circuit protection insures the wiring doesn’t overheat and start a fire.

Identify each power circuit and determine the required wire size and circuit protection. The right wire size insures the circuit can deliver the required load current. The right circuit protection insures the wiring doesn’t overheat and start a fire.

- Select power wire size based on load current

- Select power circuit protection based on wire size.

Then determine the best power component type to use based on function and select the right size based on voltage and load current. The right type insures it’ll function as desired and the right size insures it’ll reliably handle the load.

3 • use the best control type

Always start with simple control components (Relays, Timers, etc.) When simple does’t get the job done, use something with more functionality like a programmable Smart Relay or a Programmable Logic Controller (PLC). These provide significantly more functionality, but they also require a computer and programming software and someone who knows how to program the desired functionality.

Some control panel designers start with a Programmable Logic Controller (PLC). Sometimes a PLC is the way to go, but you should always use the simplest control type appropriate to the application.

4 • use the best operator device type

Always start with simple operator devices (Pushbuttons, Pilot Lights, Digital Panel Meters, etc.). For a stylish appearance add a Color Graphic door laminate. When simple does’t get the job done, use a color touch screen display as the Human Machine Interface (HMI). This provides significantly more functionality, but it also requires a computer and programming software and someone who knows how to program the desired functionality.

Some control panel designers start with a Human Machine Interface (HMI). Sometimes an HMI is the way to go, but you should always use the simplest operator device type appropriate to the application.

5 • use the best in class products by category

Experienced control panel designers use the best in class products by product category. This is subjective based on product awareness. Experienced control panel designers are aware of the array of products available in a product category. This allows them to compare and use products that provide the best balance of price, form and function.

Some control panel designers try to use one manufacturer for all components in a panel. European companies tend to do this and some US companies do too. Sometimes there’s a reason why this makes sense, but generally it limits your ability to use best in class products by product category.