Control Panel Manufacturer Software isn’t a single piece of software you buy that comes ready to use out of the box. Several software companies pitched us their one size fits all control panel manufacturer software. When we decided they were too expensive and incomplete, we decided to write our own.

Control Panel Manufacturer Software isn’t a single piece of software you buy that comes ready to use out of the box. Several software companies pitched us their one size fits all control panel manufacturer software. When we decided they were too expensive and incomplete, we decided to write our own.

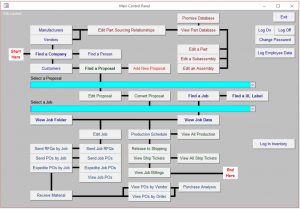

Our software is simple, fast, accurate and repeatable. Instead of trying to make it do everything we decided to use out of the box software to perform specific functions and wrote interfaces to them. Our software sends data and instructions to each application so it can do its job.

The software applications that make up our control panel manufacturer software are

- MS Access – We use Access to develop our control panel manufacturer software called Isaac.

- MS SQL – We use SQL as our database.

- MS Explorer – We use Explorer to open and move directories and files as needed

- MS Excel – We use Excel to format and transfer data between applications

- MS Visual Studio – We use Visual Studio to manipulate and transfer data between applications

- Adobe Acrobat – We use Acrobat to print and open PDF files and generate submittal packages

- Bentley Microstation – We use Microstation V8i as our design platform.

- MS Project – We use Project to schedule parts flow, production, quality control, shipping.

Control Panel Manufacturer success starts with being able to produce fast accurate control panel quotes. Fast means you can meet short deadlines. Accurate means you can provide the lowest price without missing anything. The first steps of our control panel manufacturing process are as follows.

1 • Preparing a control panel quote

Most of our customers produce flexible equipment packages they configure to customer specification. When our customers need a quote for one or more control panels for a project, they send us their customer’s specification and we quote the control panels to their specification.

When a new quote is similar to a previous one, customers will reference the previous quote and specify the required changes. In this is the case, we clone the previous quote to a new one and make the specified changes. Below is how we prepare a control panel quote.

- Customer: When we enter a new customer’s information (Physical Address, Phone, Website, etc.) and Contacts (Name, Title, Email, etc.) our system generates a unique Customer ID.

- Quote: When we prepare a new quote we select the Customer and Contact from a list, enter the Customer’s Project No. and Description, and our system generates a unique Quote ID.

- Quote Panels: When we add new panels to a quote, we enter the Panel Name and Quantity, and our system generates a unique Panel ID. We change a Panel Sort No to organize the list.

- Panel Parts: When we add new parts to a panel, we select each from a list, enter its Device ID and Description, and our system generates a unique Panel Part ID. We change a Part Sort No to organize the list as follows:

- Enclosure Components (Enclosures, Accessories, etc.)

- Power Circuit Components (Circuit Breakers, Contactors, etc.)

- Control Circuit Components (Relays, Time Delays, etc.)

- Operator Devices (Pilot Devices, Panel Meters, etc.)

- Special Components (PLC, HMI, etc.)

- Wire Management (Wire Duct, DIN Rail, etc.)

- Terminals (1 Tier Terminals, 2 Tier Terminals, etc.)

Initial (Automatic) Cost Calculations

- Calculate Material by Panel.

- Material cost calculated as part Quantity times its Base Price and Multiplier.

- Calculate Total Material by summing the Material cost of all parts.

- Calculate Labor cost by Panel.

- Part attributes are part Quantity times its Attributes.

- Part attributes (for all parts) are summed.

- Labor hours are Part Attributes times the Labor Matrix.

- Labor costs are Labor Hours times their Hourly Rate.

- Calculate Total labor by summing all labor costs.

- Calculate Shipping cost by Panel.

- Part weight is Quantity times its Weight.

- Total weight is calculated by summing the weight of all parts.

- Shipping cost calculation based on weight.

Repeat (Manual) Cost Calculations

- Many customers have several standard panel designs. In our system each one starts as a first prototype using the calculations above.

- After the first prototype has been produced, tested, shipped, modified, and finally accepted by our customer as a their Standard Panel we’ll build a Standard Panel (Part No / Name) Assembly in our database consisting of

- Exact Bill of Materials used to produce the first prototype panel

- Manually set Design and CAD hours to near zero because exact replica of the first prototype panel.

- Manually set Manufacturing and Quality Control hours set based on desired production quantity.

- Calculate Material based on the automatic calculations above.

- Calculate Labor cost based on the manually set labor hours and their hourly cost

- Shipping cost calculated based on weight.

2 • Generating a Control Panel Submittal

The beauty of our process is every step prepares the requirements for the next step. At this point, we’ve produced a Control Panel Quote with detailed design and production data.

Most of our customers produce equipment packages configured to meet their customer’s specified requirements. When our customers receive an order, they have to generate and send an equipment submittal package to their customer for Review and Approval prior to releasing their customer’s order to production.

When our customers receive an order, we generate and send them a Control Panel Submittal. They include it in their equipment submittal package for Review and Approval by their Customer.

3 • Converting a Quote to an Order

If the Quote turns into an Order, we can import the design information (Part No, Device ID, Description) into our panel design software and use the Labor Hours (Des, CAD, Mfg, QC) to accurately schedule production.